Antonio Lorenzo-Espejo1![]() , Alejandro Escudero-Santana1

, Alejandro Escudero-Santana1![]() , María-Luisa Muñoz-Díaz1

, María-Luisa Muñoz-Díaz1![]() and Alicia Robles-Velasco1

and Alicia Robles-Velasco1![]()

1 Departamento de Organización Industrial y Gestión de Empresas II, Escuela Técnica Superior de Ingeniería, Universidad de Sevilla, Cm. de los Descubrimientos, s/n, 41092 Seville, Spain.

Keywords: Machine Learning, Regression, Process control, Wind power, Lead time, Bending.

1. Introduction

The goal of this study is to analyze and predict the completion time of a main process of wind tower manufacturing: bending. This is a critical step of the production process, since defects in bending can slow down posterior operations. Therefore, accurate predictions of its lead time can help detect anomalies and prevent costly repairs or even complete reworks. Additionally, the impact of several input factors is analyzed in order to provide deeper insight into the underlying patterns of the bending process.

The final product of a wind tower manufacturing plant are the sections of a tower. They are built using ferrules, smaller cylinders or cones that are welded together. At the same time, the ferrules are comprised of steel plates bent into rings, which are then welded in order to form a closed cylinder. In order to bend the plates, they are inserted through rollers lengthwise, slowly giving them a circular shape.

2. Methodology

The main goal of this study is to achieve accurate predictions of the lead time of the bending process in wind tower manufacturing and to analyze correlations between these completion times and several factors that influence this process. This has been done by building regression models through machine learning algorithms in WEKA [1].

The data utilized for the regression analyses performed in this study can be split into two categories: input variables and output variables. The output variable represents the time required to process a ferrule in the bending station (in hours). The following input variables have been suggested as potential determinants of the bending time: position of the ferrule; position of the section; work shift; personnel; machine; ferrule thickness; length of the plate; width of the plate; steel yield strength; steel toughness; and steel normalization.

The data used for this analysis corresponds to the operation of a Spanish wind tower manufacturer from 2018 to 2021. The data includes information of over 7400 ferrules.

In order to obtain a regression model, a linear regression algorithm has been employed. This technique is a fast method for obtaining models without extensive parametrizations, and can produce accurate predictions. The linear regression model is first run using a random 80/20 training-test split, and then creating cross-validation sets.

The M5P method has also been applied to both the 80/20 split and the cross-validation sets. The M5P algorithm constructs a decision tree where the leaves correspond to a set of linear regression models. When an instance is fed to the system, it arrives at one of the tree’s leaves through attribute-based decisions at the tree’s nodes. Once there, the value of the target variable is predicted utilizing the leaf’s linear regression model.

3. Results

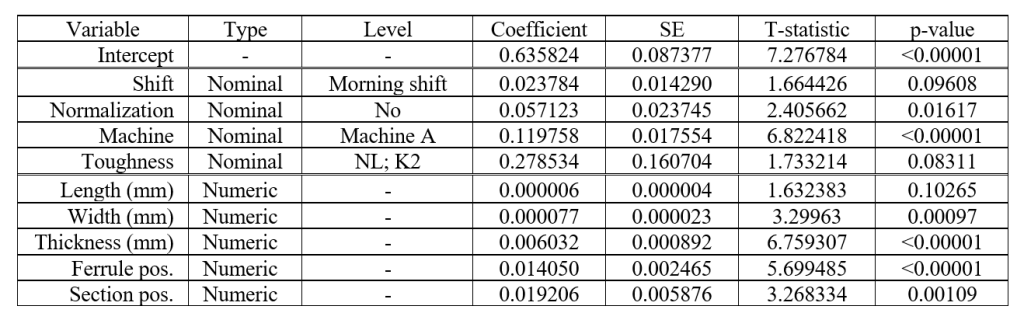

Table 1 shows the coefficients determined for each variable in the 80/20 training-test split linear regression experiment, as well as their standard error and significance.

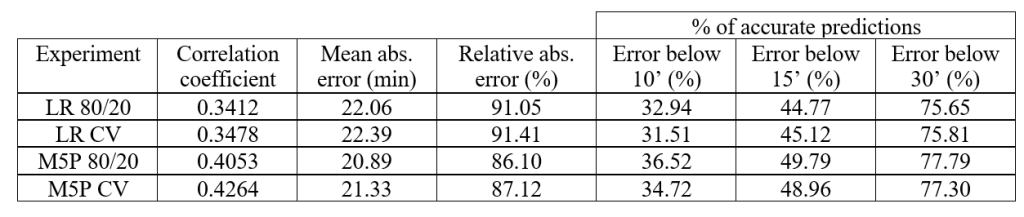

The performances of this linear regression model and the M5P method have been evaluated with a test dataset comprised of over 1,450 operations, as well as with a ten-fold-cross-validation. The main performance statistics are presented in Table 2.

Overall, the machine learning algorithms show a moderate predictive power. The proposed models will predict the lead time with less than a 10-minute error in 30-35% of the occasions.

References

- WEKA, https://www.cs.waikato.ac.nz/ml/weka/, last accessed 2021/01/10.