Diego Rorato Fogaça1,2,3![]() , Mercedes Grijalvo1

, Mercedes Grijalvo1![]() , and Mario Sacomano Neto2

, and Mario Sacomano Neto2![]()

1 Universidad Politécnica de Madrid (UPM), Madrid, Spain

2 Federal University of São Carlos (UFSCar), São Carlos, SP, Brazil

3 Federal University of Mato Grosso do Sul (UFMS), Campo Grande, MS, Brazil

Keywords: Industry 4.0, Digitalization, Institutional Theory

1. Introduction

The term “Industry 4.0” is becoming increasingly common to refer to the fourth industrial revolution. It is based on complex digital systems that, when integrated into networks and automated processes, bring together physical and virtual objects which support an even more flexible and customized industrial mass production [1]. It offers opportunities and promotes changes in markets, business models, supply chains, and in the world of work. Some authors discuss the Industry 4.0 is a discourse to institutionalize innovation in manufacturing systems [2] or a project to ensure Germany’s leadership in high-quality industrial production and exports [3]. In other words, there are relevant institutional issues in the origins and dissemination of Industry 4.0. An institutional perspective can therefore bring valuable insights to the phenomenon. The paper aims to investigate how and to what extent the institutional theory has been used to understand Industry 4.0. For this, a systematic literature review (SRL) is performed.

2. Methods

The SLR’s objective was to find articles that simultaneously addressed the concepts of “Industry 4.0” and “Institutional Theory”. The application of selection criteria resulted in the selection of 19 articles, which were fully read. Since few documents were located, the search was expanded to include the concept of “digital transformation” that is connected but is broader than the definition of Industry 4.0. The software IRAMUTEQ was utilized to analyze the articles’ abstracts.

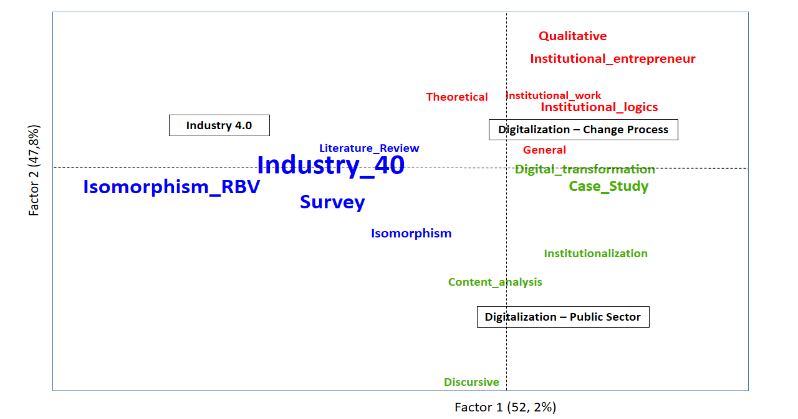

We used two multivariate techniques. The Descending Hierarchical Classification (DHC) displays stable word classes with a vocabulary similar to each other and different from other classes. The Correspondence Factor Analysis (CFA) shows the association and opposition between words or texts (Fig. 1). Such techniques reduce a large number of observed variables to a small number of factors. The factors represent the latent constructs that explain the set of observed variables.

3. Results

From the 64 abstracts (19 related to Industry 4.0 and 45 related to digitalization), the DHC generated three thematic classes identified as Industry 4.0 (blue), digitization in the public sector (green) and process of change related to digitization (red). To generate Fig. 1 showing the CFA, each of the abstracts was classified according to its theme (Industry 4.0 or digital transformation), the research method used and the underlying institutional theory.

The horizontal axis clearly distinguishes Industry 4.0 from digitalization (in red and green). Industry 4.0 is associated with institutional isomorphism and the survey method. Digitalization stands out for its association with the theories of institutional logics, institutional entrepreneurship and institutional work. Qualitative and case study methods account for more than 60% of the articles concerning digitalization.

4. Conclusion

A limitation of this SLR is that it did not focus on a detailed bibliometric analysis. Nevertheless, the method adopted here demonstrated the suitability of an exploratory investigation of articles’ abstracts through multivariate analysis using free software. Results indicate few studies apply institutional theory to understand Industry 4.0. We identify promising new avenues of research from methodological and theoretical micro, meso and macro perspectives. Qualitative or mixed methods can bring significant insights when combined with concepts of institutional logics or institutional work (micro). Social movements and an empirical definition of organizational fields can support a meso analysis of Industry 4.0. Along with this, considerations about national particularities (macro) can help understand Industry 4.0 development in different countries.

Acknowledgments. The authors would like to acknowledge the Spanish Agencia Estatal de Investigación, through the research project with code RTI2018-094614-B-I00 into the “Programa Estatal de I+D+i Orientada a los Retos de la Sociedad”

References

- Lasi, H. et al.: Industry 4.0. Bus. Inf. Syst. Eng. 6, 239–242 (2014).

- Reischauer, G.: Industry 4.0 as policy-driven discourse to institutionalize innovation systems in manufacturing. Technol. Forecast. Soc. Change. 132, 26–33 (2018).

- Arbix, G. et al.: Advanced Manufacturing: What Is to Be Learnt from Germany, the U.S., and China. Novos Estud CEBRAP. 36, 29–49 (2017).